FEA CONSULTING

Shear Development is an FEA consulting firm focused on providing our clients with world class simulation solutions. We work meticulously to produce accurate and cost-effective simulations that will lower your bottom line and get your product to market faster.

Our analysis engineers have proven experience leveraging state of the art FEA tools to solve complex engineering challenges. Our solutions have been validated, correlated and continue to prove themselves in the real-world every day.

WHY FEA?

Save on Product Development / Life Cycle Costs

- Discover your design challenges and update / iterate early to avoid expensive changes further down the road.

- Test virtually and produce mature prototypes that will pass criteria, and reduce overall prototype / lab costs.

- Use FEA services to reduce critical failures, warranty costs and equipment downtime.

Bring High Quality Products to Market – Faster

- Continually beat your competitors to market by using engineering analysis to understand and optimize your design early on.

- Use simulation to test multiple parameters quickly and effectively.

FEA Services Include:

- Linear – Static / Structural Stress Analysis

- Complex Assembly Analysis

- Dynamic / Vibration Analysis

- Failure Analysis

- Kinematic Analysis

- Topology Optimization

- Impact Analysis (Drop Test)

- Durability & Fatigue Analysis

- Non-linear analysis: post-yield material, material nonlinearity, geometric nonlinearity, nonlinearity due to contact

FEA CONSULTING WORK SAMPLES

?>Live

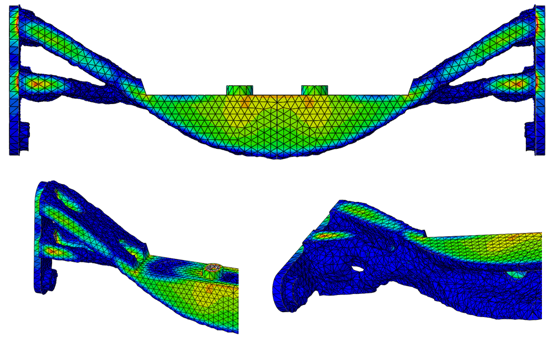

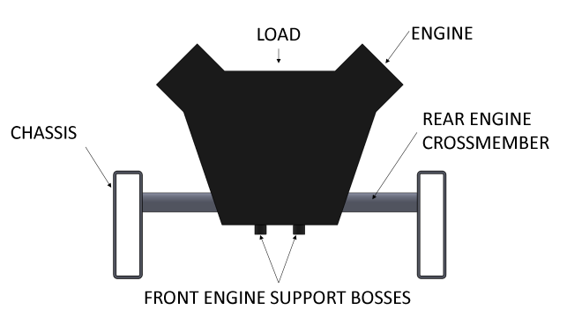

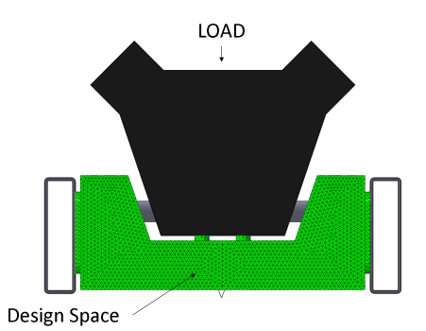

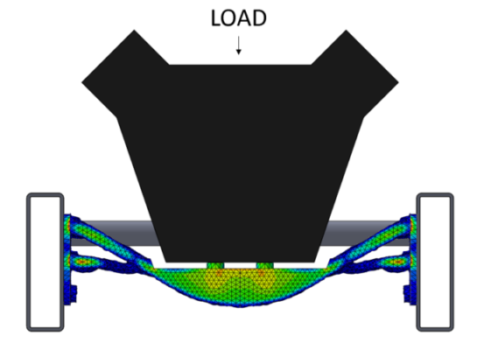

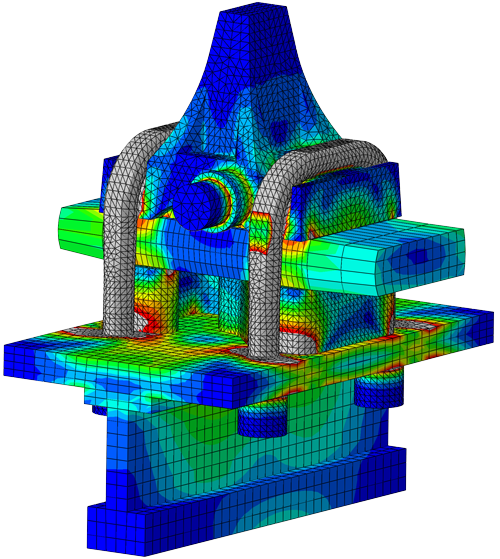

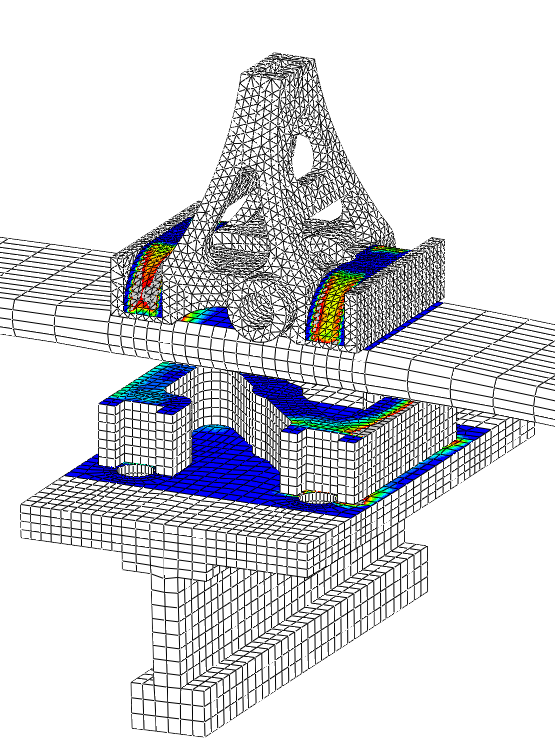

Topology Optimization - Engine Mount

Analysis Type: Topology Optimization

Overview: When tasked to push the envelope to reduce cost and weight, topology optimization is the perfect tool to provide direction. Our team leveraged topology optimization FEA tools and delivered an ideal 3D footprint to kick off design.

+ VIEW DETAILS

Live

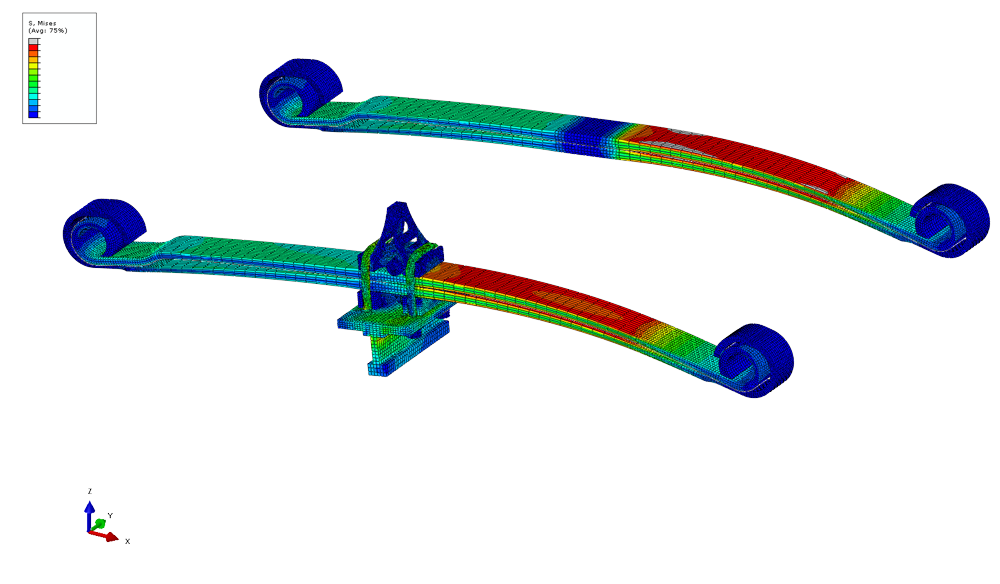

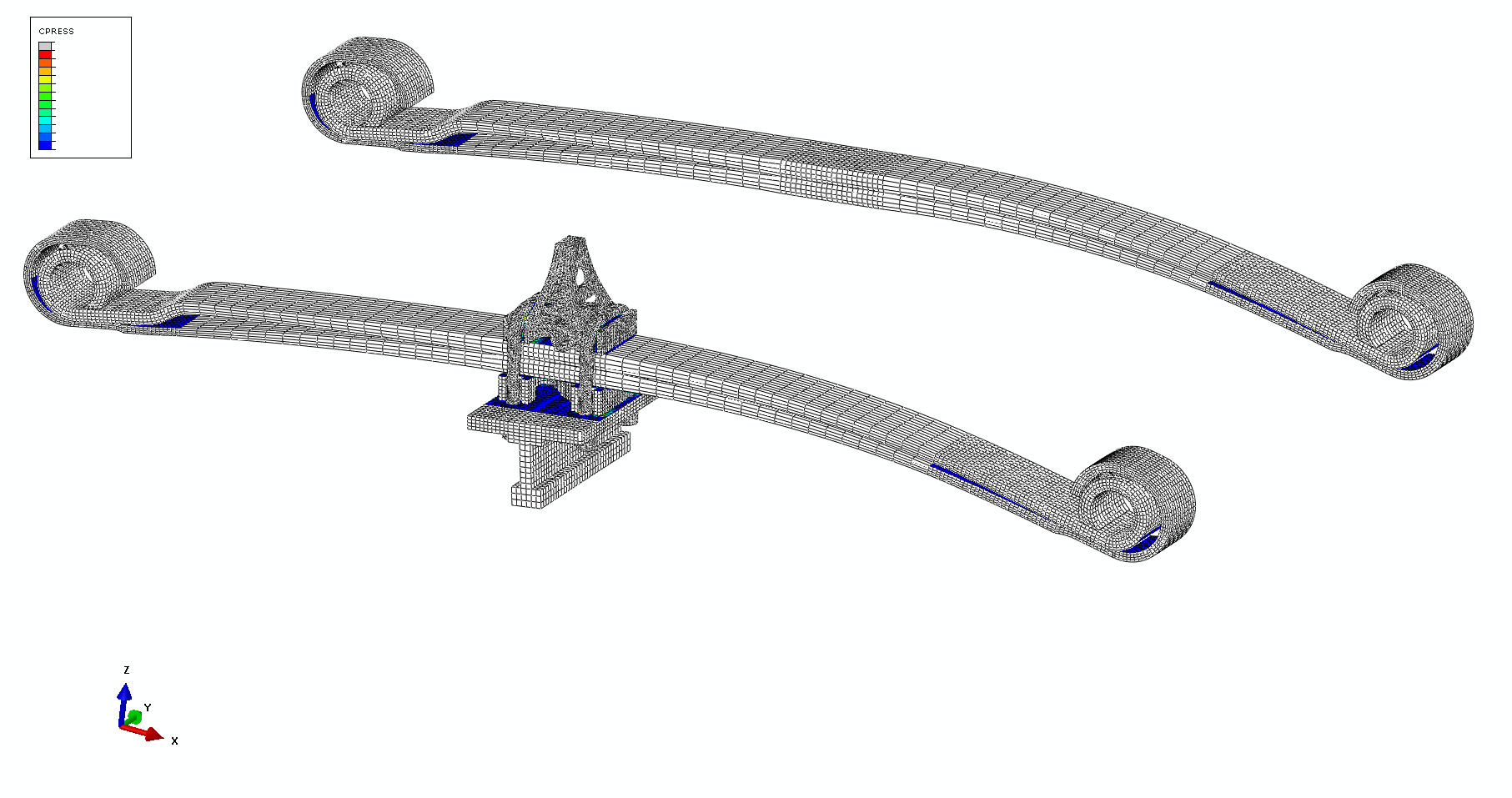

Front Suspension Leaf Spring and Clamp Group

Analysis Type: Finite Element Analysis

Overview: Finite Element Analysis was used to further understand the behavior of a leaf spring front suspension. The simulations successfully verified the suspensions kinematics and were leveraged to analyze the stresses in individual clamp group components.

+ VIEW DETAILS

FEA CONSULTING WORK SAMPLES

Topology Optimization - Engine Mount

Analysis Type: Topology Optimization

Overview: When tasked to push the envelope to reduce cost and weight, topology optimization is the perfect tool to provide direction. Our team leveraged topology optimization FEA tools and delivered an ideal 3D footprint to kick off design.

+ VIEW DETAILS

Front Suspension Leaf Spring and Clamp Group

Analysis Type: Finite Element Analysis

Overview: Finite Element Analysis was used to further understand the behavior of a leaf spring front suspension. The simulations successfully verified the suspensions kinematics and were leveraged to analyze the stresses in individual clamp group components.

+ VIEW DETAILS